Precision Machining Technology 3rd Edition PDF: An Article Plan

This article delves into the comprehensive Precision Machining Technology 3rd Edition, focusing on its PDF availability and content.

We’ll explore Hoffman and Hopewell’s work, examining its ISBNs (9781337795432, 1337795437) and eText format.

The plan outlines key areas, from foundational concepts to advanced CNC programming and practical applications within the field.

Precision Machining Technology stands as a cornerstone resource for aspiring and practicing machinists, engineers, and technicians. The 3rd Edition, authored by Peter J. Hoffman and Eric S. Hopewell, builds upon a strong foundation, offering an updated and expanded exploration of modern machining principles. This textbook isn’t merely a theoretical overview; it’s a practical guide designed to bridge the gap between classroom learning and real-world shop floor applications.

The core aim of this text is to equip readers with a thorough understanding of both manual and CNC machining processes. It emphasizes the importance of precision, accuracy, and quality control – essential elements in today’s manufacturing landscape. The availability of a PDF version enhances accessibility, allowing students and professionals to study and reference the material conveniently. Understanding the fundamentals presented within this edition is crucial for success in a rapidly evolving industry.

This book serves as a vital resource for anyone seeking to master the art and science of precision machining.

Understanding the 3rd Edition Updates

The 3rd Edition of Precision Machining Technology represents a significant evolution from its predecessors, reflecting advancements in the field and incorporating feedback from educators and industry professionals. Updates extend beyond simply revising existing content; substantial new material has been added to address emerging technologies and techniques. A key focus is the expanded coverage of CNC programming and automation, reflecting the increasing dominance of computer-controlled machinery.

The PDF version benefits from these revisions, providing access to the most current information available. Enhanced illustrations and detailed examples further clarify complex concepts. The authors have also strengthened the emphasis on metrology and quality control, recognizing their critical role in modern manufacturing. This edition also includes updated safety protocols and best practices, ensuring students are prepared for a safe and productive work environment. Accessing the PDF ensures learners have the latest insights.

Core Concepts Covered in the Textbook

Precision Machining Technology, in its 3rd Edition PDF format, systematically builds understanding from fundamental principles to advanced techniques. Core concepts begin with material science, exploring the properties of metals, plastics, and composites commonly used in machining. Geometric Dimensioning and Tolerancing (GD&T) receives substantial attention, crucial for interpreting engineering drawings and ensuring part accuracy.

The textbook thoroughly covers cutting tool technology, detailing tool materials, geometries, and applications. Students gain insight into various machining processes, including turning, milling, drilling, and grinding. Furthermore, the PDF emphasizes the importance of metrology – the science of measurement – and quality control procedures. Understanding these core concepts, presented clearly within the PDF, is essential for success in precision machining, preparing individuals for real-world challenges.

Machining Processes Detailed in the PDF

The Precision Machining Technology 3rd Edition PDF provides in-depth coverage of essential machining processes. Turning operations are explored with detailed explanations of various turning methods, tool selection, and setup procedures. Milling operations receive similar attention, covering face milling, end milling, and other techniques, alongside discussions on cutter geometry and feed rates.

Beyond these, the PDF meticulously details drilling and reaming processes, emphasizing hole-making accuracy and surface finish. The text also extends to grinding, broaching, and other specialized machining methods. Each process is explained with practical examples and illustrations, enhancing comprehension. The PDF format allows for easy access to these detailed explanations, making it a valuable resource for students and professionals alike seeking mastery of these core machining techniques.

Turning Operations

The Precision Machining Technology 3rd Edition PDF dedicates significant attention to turning operations, a cornerstone of machining. It comprehensively covers various turning methods, including straight turning, taper turning, and contour turning, detailing the setup and tooling required for each. The PDF explains the importance of selecting appropriate cutting speeds and feeds for different materials, optimizing both efficiency and surface finish.

Furthermore, it delves into specialized turning techniques like threading and grooving, providing practical guidance on tool geometry and process parameters. The text emphasizes safety procedures specific to lathe operation, ensuring responsible machining practices. Diagrams and illustrations within the PDF visually demonstrate the mechanics of turning, aiding in understanding. This section is crucial for anyone seeking a thorough grasp of turning principles and applications.

Milling Operations

The Precision Machining Technology 3rd Edition PDF provides an in-depth exploration of milling operations, a versatile machining process. It details various milling techniques, including face milling, end milling, and slotting, outlining the appropriate tooling and machine setups for each. The PDF emphasizes the importance of cutter selection based on material and desired finish, covering high-speed steel, carbide, and ceramic cutters.

Furthermore, it explains climb milling versus conventional milling, detailing the advantages and disadvantages of each approach. The text thoroughly covers coolant application and its impact on tool life and surface quality. Diagrams within the PDF illustrate different milling cutter geometries and their applications. This section is vital for understanding the principles and practical aspects of milling, essential for precision manufacturing.

Drilling and Reaming

The Precision Machining Technology 3rd Edition PDF dedicates a significant portion to drilling and reaming, fundamental hole-making processes. It comprehensively explains different drill types – twist drills, spade drills, and core drills – detailing their applications and limitations. The PDF emphasizes proper drill selection based on material hardness and hole diameter, alongside techniques for accurate hole positioning and size control.

Reaming, as a finishing operation, is thoroughly covered, explaining its role in achieving precise hole dimensions and surface finishes. The text details various reamer types – straight fluted, spiral fluted, and shell reamers – and their respective advantages. Coolant usage and feed rates are discussed to optimize reaming performance and prevent tool wear. Diagrams within the PDF illustrate proper drilling and reaming setups for optimal results.

Materials Used in Precision Machining

The Precision Machining Technology 3rd Edition PDF provides an extensive overview of materials commonly encountered in precision machining. It categorizes these materials into ferrous and non-ferrous groups, detailing their unique properties and machinability characteristics. Ferrous materials like carbon steels, alloy steels, and cast irons are examined, focusing on hardness, tensile strength, and thermal conductivity.

Non-ferrous materials, including aluminum, brass, copper, and titanium, receive similar detailed attention. The PDF highlights how material composition impacts cutting tool selection, speeds, and feeds. It also discusses emerging materials like polymers and composites, outlining their specific machining challenges and best practices. Understanding these material properties, as presented in the PDF, is crucial for achieving optimal machining results and component quality.

Cutting Tools and Their Applications

The Precision Machining Technology 3rd Edition PDF dedicates significant coverage to cutting tools, classifying them based on construction and application. Single-point cutting tools, used in turning and boring, are analyzed alongside multi-point tools like drills, mills, and reamers. The PDF details tool materials – high-speed steel, carbides, ceramics, and diamond – explaining their strengths and weaknesses.

It emphasizes the importance of selecting the correct tool geometry, including rake angle, clearance angle, and nose radius, for specific materials and operations. Furthermore, the PDF explores tool coatings (TiN, TiC, AlTiN) and their impact on tool life and performance. Proper tool selection, as illustrated within the PDF, directly influences surface finish, dimensional accuracy, and overall machining efficiency.

Machine Tools Explained

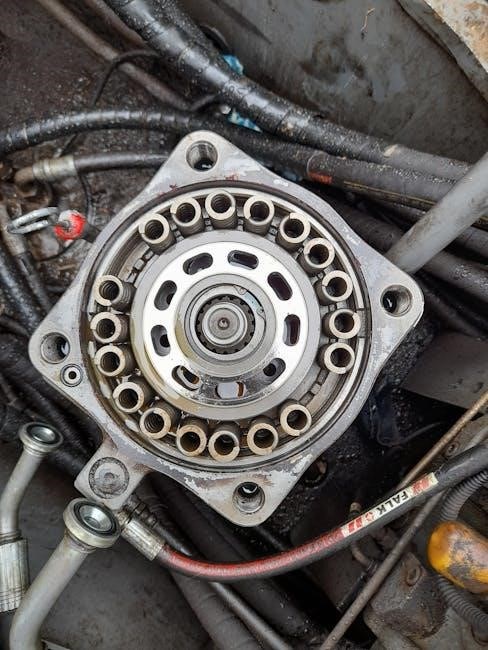

The Precision Machining Technology 3rd Edition PDF provides a detailed examination of various machine tools essential for precision manufacturing. It categorizes these tools into CNC machines and manual machines, outlining their operational principles and capabilities. The PDF thoroughly explains the components of common machine tools like lathes, milling machines, and grinders.

A significant portion focuses on CNC machine technology, covering control systems, programming methods, and automation features. The PDF illustrates how CNC machines enhance accuracy, repeatability, and production rates. Conversely, it also details the advantages of manual machines for prototyping and low-volume production. Diagrams and illustrations within the PDF aid in understanding the mechanics and functionality of each machine type.

CNC Machines

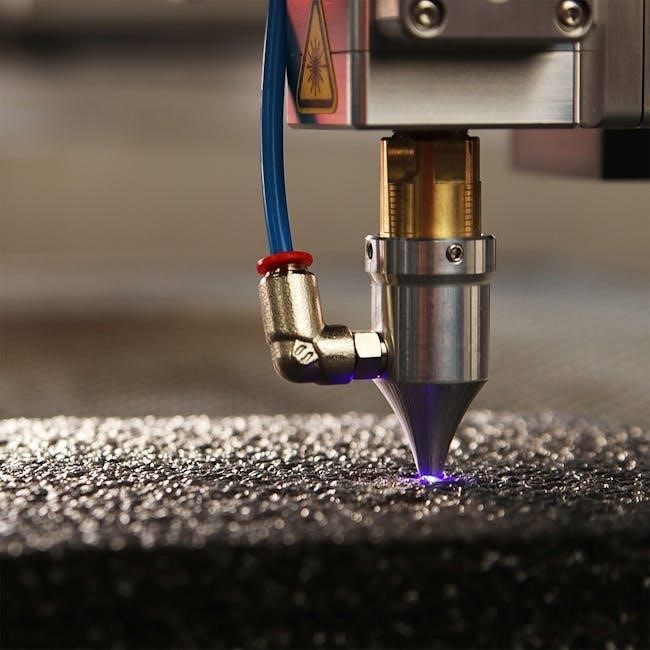

The Precision Machining Technology 3rd Edition PDF dedicates substantial coverage to CNC (Computer Numerical Control) machines, the cornerstone of modern precision machining. It details the architecture of CNC systems, including the controller, drives, and feedback mechanisms. The PDF explains various CNC machine types, such as CNC lathes, milling centers, and machining centers, highlighting their specific applications.

Furthermore, the text within the PDF explores CNC programming techniques, including G-code and M-code, essential for instructing the machines. It emphasizes the importance of toolpath generation and optimization for efficient machining. The PDF also covers advanced CNC features like tool changers, pallet systems, and multi-axis machining, demonstrating how these technologies enhance productivity and complexity.

Manual Machines

Despite the prevalence of CNC technology, the Precision Machining Technology 3rd Edition PDF maintains significant attention to manual machines, recognizing their continued relevance and foundational importance. The PDF provides detailed explanations of manual lathe and milling machine operations, covering setup procedures, cutting tool selection, and speed/feed calculations.

It thoroughly illustrates techniques for performing operations like turning, facing, threading, milling, and drilling on manual equipment. The text emphasizes the development of manual dexterity and understanding of machining principles, skills crucial for troubleshooting and adapting to various machining scenarios. The PDF also covers essential accessories and tooling used with manual machines, ensuring a comprehensive understanding of traditional machining practices.

Metrology and Quality Control

The Precision Machining Technology 3rd Edition PDF dedicates substantial coverage to metrology and quality control, recognizing their critical role in achieving precision manufacturing. It details various measurement tools and techniques, including calipers, micrometers, height gauges, and coordinate measuring machines (CMMs).

The PDF explains how to accurately measure dimensions, assess surface finish, and identify potential defects; Statistical process control (SPC) methods are also explored, enabling machinists to monitor and improve process capability. Emphasis is placed on understanding measurement uncertainty and proper calibration procedures. Furthermore, the text covers inspection techniques and the interpretation of engineering drawings to ensure parts meet specified tolerances, vital for maintaining product quality and reliability.

Geometric Dimensioning and Tolerancing (GD&T)

The Precision Machining Technology 3rd Edition PDF provides a thorough introduction to Geometric Dimensioning and Tolerancing (GD&T), a crucial aspect of modern engineering drawings. It explains the symbolic language used to define permissible variations in part geometry, going beyond traditional plus-or-minus tolerancing.

The PDF details various GD&T symbols, including flatness, straightness, circularity, cylindricity, parallelism, perpendicularity, angularity, and position. It clarifies how these symbols control form, orientation, and location. Understanding GD&T is presented as essential for interpreting designs accurately, ensuring proper manufacturing processes, and facilitating effective communication between designers and machinists. The text emphasizes how GD&T impacts functionality and interchangeability of manufactured parts, leading to improved quality and reduced costs.

Programming for CNC Machines

The Precision Machining Technology 3rd Edition PDF dedicates significant coverage to CNC machine programming, a cornerstone of modern precision machining. It moves beyond manual operation, focusing on how to instruct computer-controlled machines to execute complex operations.

The PDF likely explores various programming methods, potentially including G-code and conversational programming. It details how to write code for different machining processes – turning, milling, and drilling – emphasizing toolpath generation, feed rates, and spindle speeds. The resource aims to equip readers with the skills to create efficient and accurate programs, optimizing machining parameters for specific materials and geometries. Understanding CNC programming is presented as vital for maximizing machine capabilities and achieving high-precision results.

Safety Procedures in Precision Machining

The Precision Machining Technology 3rd Edition PDF places paramount importance on safety protocols within the machining environment. Recognizing the inherent hazards of operating powerful machinery, the text likely dedicates a substantial section to preventative measures and best practices.

This includes detailed guidance on personal protective equipment (PPE) – safety glasses, hearing protection, and appropriate clothing. The PDF probably covers machine guarding, emergency stop procedures, and safe handling of cutting tools and materials. It emphasizes the importance of proper ventilation, fire prevention, and awareness of potential hazards like flying chips and rotating parts. A comprehensive understanding of these safety procedures, as detailed in the resource, is crucial for preventing accidents and maintaining a safe working environment.

Applications of Precision Machining

The Precision Machining Technology 3rd Edition PDF showcases the incredibly diverse applications of this critical manufacturing process. The text likely illustrates how precision machining is fundamental across numerous industries, including aerospace, automotive, medical device manufacturing, and electronics.

Expect to find examples detailing the creation of complex components for jet engines, intricate automotive parts demanding tight tolerances, and highly precise medical implants. The PDF probably highlights the role of precision machining in producing micro-scale components for electronic devices. It demonstrates how advancements in CNC technology, covered within the resource, enable the creation of increasingly sophisticated and specialized parts, driving innovation and efficiency across various sectors.

Resources and Further Learning

Beyond the Precision Machining Technology 3rd Edition PDF itself, numerous resources bolster understanding of this field. The textbook likely references professional organizations like the National Tooling and Machining Association (NTMA) and SME (Society of Manufacturing Engineers), offering certifications and training programs.

Online platforms such as Coursera and Udemy provide supplementary courses on CNC programming, GD&T, and machining principles. Manufacturers like Haas and Mazak often offer their own training academies. Exploring industry publications – Modern Machine Shop and Precision Manufacturing – keeps practitioners updated on the latest technologies. The PDF may also point to relevant software tutorials and simulation tools, enhancing practical skills and solidifying theoretical knowledge for continued professional development.

Where to Download the 3rd Edition PDF

Locating a legitimate Precision Machining Technology 3rd Edition PDF requires careful navigation. While direct downloads from the publisher (Cengage) often require purchase or institutional access, exploring online libraries and educational resource platforms may yield results. Be cautious of unofficial sources, prioritizing legal and ethical acquisition to respect copyright.

Checking university or college online bookstores can sometimes reveal PDF options for enrolled students. Searching academic databases and digital lending libraries might also prove fruitful. Remember to verify the file’s integrity and authenticity before downloading. Always prioritize legally obtained copies to support the authors, Peter Hoffman and Eric Hopewell, and ensure access to the most accurate and up-to-date content.